Specialist Thermal Cleaning Services

Innovative Thermal Cleaning for a Wide Range of Sectors

A Unique Service in Ireland

As one of the few companies in Ireland offering specialized electric kiln thermal cleaning with gas afterburner technology, Autojob provides an unmatched solution not available from local competitors. Whether you’re in automotive, energy, marine, aerospace, plastics, paint, or another industry, our precision thermal cleaning process guarantees the highest standard of cleanliness and efficiency for your parts and equipment.

Specialist Thermal Cleaning Services for Diverse Industries

At Autojob, we offer advanced electric kiln thermal cleaning with a gas afterburner to ensure an environmentally responsible and highly effective solution for cleaning large, contaminated items. Designed for industries requiring precise handling, high-temperature cleaning, and a strong commitment to sustainability, our process delivers outstanding results.

Why Choose Our Thermal Cleaning?

- Unmatched Size and Capacity – Our kiln accommodates large, heavy items, with internal dimensions of 1000mm x 1000mm x 1000mm, making it ideal for specialized industrial components.

- High-Temperature Precision – The kiln can reach a maximum temperature of 1000°C, but the exact temperature used is defined by the materials and customer requirements, ensuring the complete removal of organic contaminants such as oils, resins, and crystallized substances without damaging materials.

- Three-Stage Cleaning Process for Superior Results

- Ramp Stage – The temperature is gradually increased to avoid thermal shock and ensure even heating.

- Soak Stage – The kiln maintains a steady high temperature, allowing contaminants to fully break down before removal. The pyrolysis process ensures that parts are heated in an oxygen-deprived atmosphere, preventing thermal runaway and ensuring controlled, safe decomposition of contaminants.

- Cooling Stage – A controlled cooling process prevents material stress, warping, or fracturing, ensuring the integrity of cleaned components.

- Eco-Friendly Process with Afterburner Technology – Our gas afterburner system burns off smoke and emissions, ensuring a zero-harm environmental impact with no harmful pollutants released.

A Unique Service in Ireland

As one of the few companies in Ireland offering specialized electric kiln thermal cleaning with gas afterburner technology, Autojob provides an unmatched solution not available from local competitors. Whether you’re in automotive, energy, marine, aerospace, plastics, paint, or another industry, our precision thermal cleaning process guarantees the highest standard of cleanliness and efficiency for your parts and equipment.

Specialist Thermal Cleaning Services for Diverse Industries

At Autojob, we offer advanced electric kiln thermal cleaning with a gas afterburner to ensure an environmentally responsible and highly effective solution for cleaning large, contaminated items. Designed for industries requiring precise handling, high-temperature cleaning, and a strong commitment to sustainability, our process delivers outstanding results.

Why Choose Our Thermal Cleaning?

- Unmatched Size and Capacity – Our kiln accommodates large, heavy items, with internal dimensions of 1000mm x 1000mm x 1000mm, making it ideal for specialized industrial components.

- High-Temperature Precision – The kiln can reach a maximum temperature of 1000°C, but the exact temperature used is defined by the materials and customer requirements, ensuring the complete removal of organic contaminants such as oils, resins, and crystallized substances without damaging materials.

- Three-Stage Cleaning Process for Superior Results

- Ramp Stage – The temperature is gradually increased to avoid thermal shock and ensure even heating.

- Soak Stage – The kiln maintains a steady high temperature, allowing contaminants to fully break down before removal. The pyrolysis process ensures that parts are heated in an oxygen-deprived atmosphere, preventing thermal runaway and ensuring controlled, safe decomposition of contaminants.

- Cooling Stage – A controlled cooling process prevents material stress, warping, or fracturing, ensuring the integrity of cleaned components.

- Eco-Friendly Process with Afterburner Technology – Our gas afterburner system burns off smoke and emissions, ensuring a zero-harm environmental impact with no harmful pollutants released.

Industries We Serve

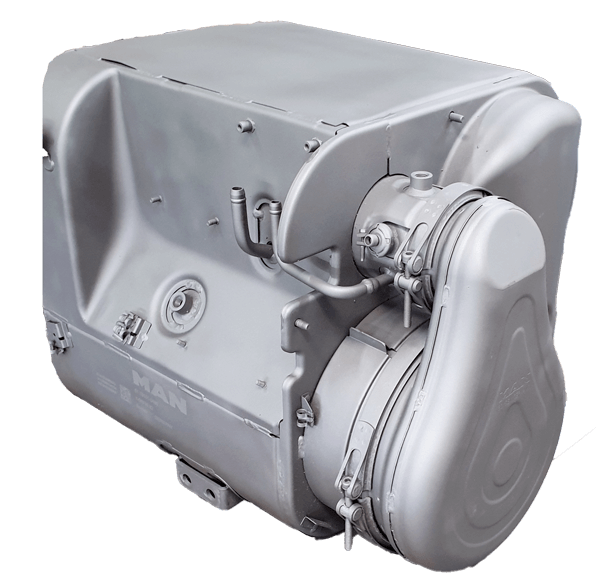

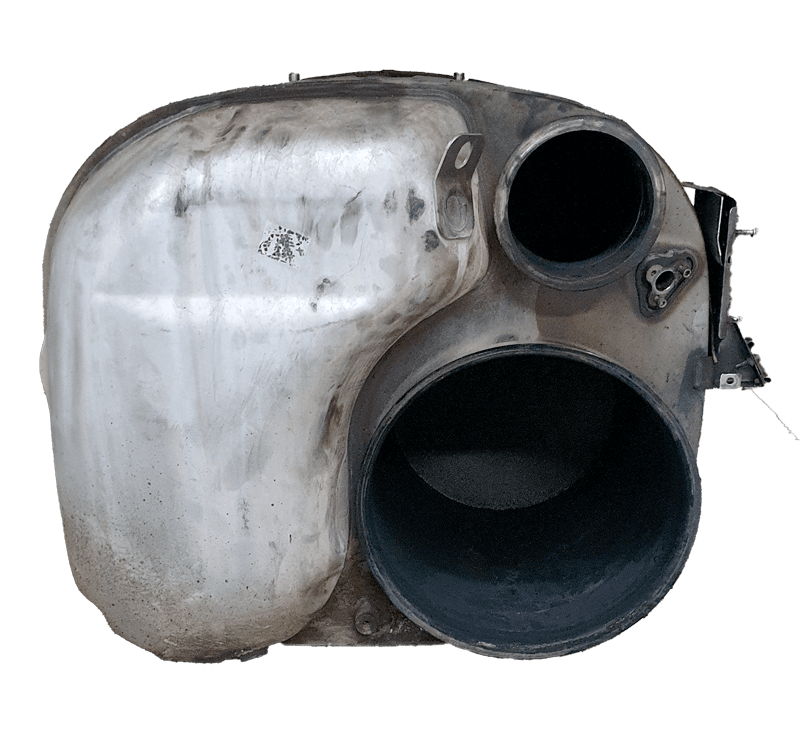

Automotive & Heavy Equipment

- Diesel Engine Exhaust Filters

- Catalytic Converters (CAT)

- Industrial Machinery Components

Energy & Power Generation

- Turbine Parts

- Heat Exchangers

- Contaminated Fuel Filters

Marine

- Exhaust Systems

- Marine Engine Filters

- Heat Transfer Equipment

Aerospace

- Aircraft Engine Parts

- Fuel Filtration Systems

- Heat Shields

Manufacturing & Heavy Industry

- Industrial Furnace Components

- Oil and Gas Industry Equipment

- Filtration Systems for Chemical Processing

Plastics & Paint Industry

- Removal of Paint, Coatings, and Polymers

- Cleaning of Plastic Moulding Equipment

- Decontamination of Industrial Filters

Food Processing & Pharmaceuticals

- Contaminated Equipment Parts

- Packaging Machinery Components

- Specialized Filters

How Thermal Cleaning Benefits Your Industry

- Thorough Cleaning for Enhanced Performance – Our kiln completely burns off organic matter, restoring filters and parts to optimal condition, improving performance, and extending equipment lifespan.

- Precision Cleaning for Complex Parts – The controlled temperature ramp, soak stage, and gradual cooling prevent material stress, fracturing, or warping, ensuring delicate components remain intact.

- Environmentally Responsible Solution – Our afterburner system ensures that no harmful emissions are released into the atmosphere, making our cleaning process a responsible choice for businesses prioritizing sustainability.

Get in Touch for a Customized Solution

Are you ready to enhance the efficiency and sustainability of your industrial cleaning processes? Contact Autojob today to discuss how our thermal cleaning technology can benefit your business. Our expert team is here to provide tailored solutions to meet your needs.

Get In Touch

Location

Ballylibert, Castlefreke

Clonakilty, Co. Cork

Ireland, P85 TP92

[email protected]

Opening Hours

Mon-Fri: 8:30am - 5:30pm

Sat: Closed

Sun: Closed